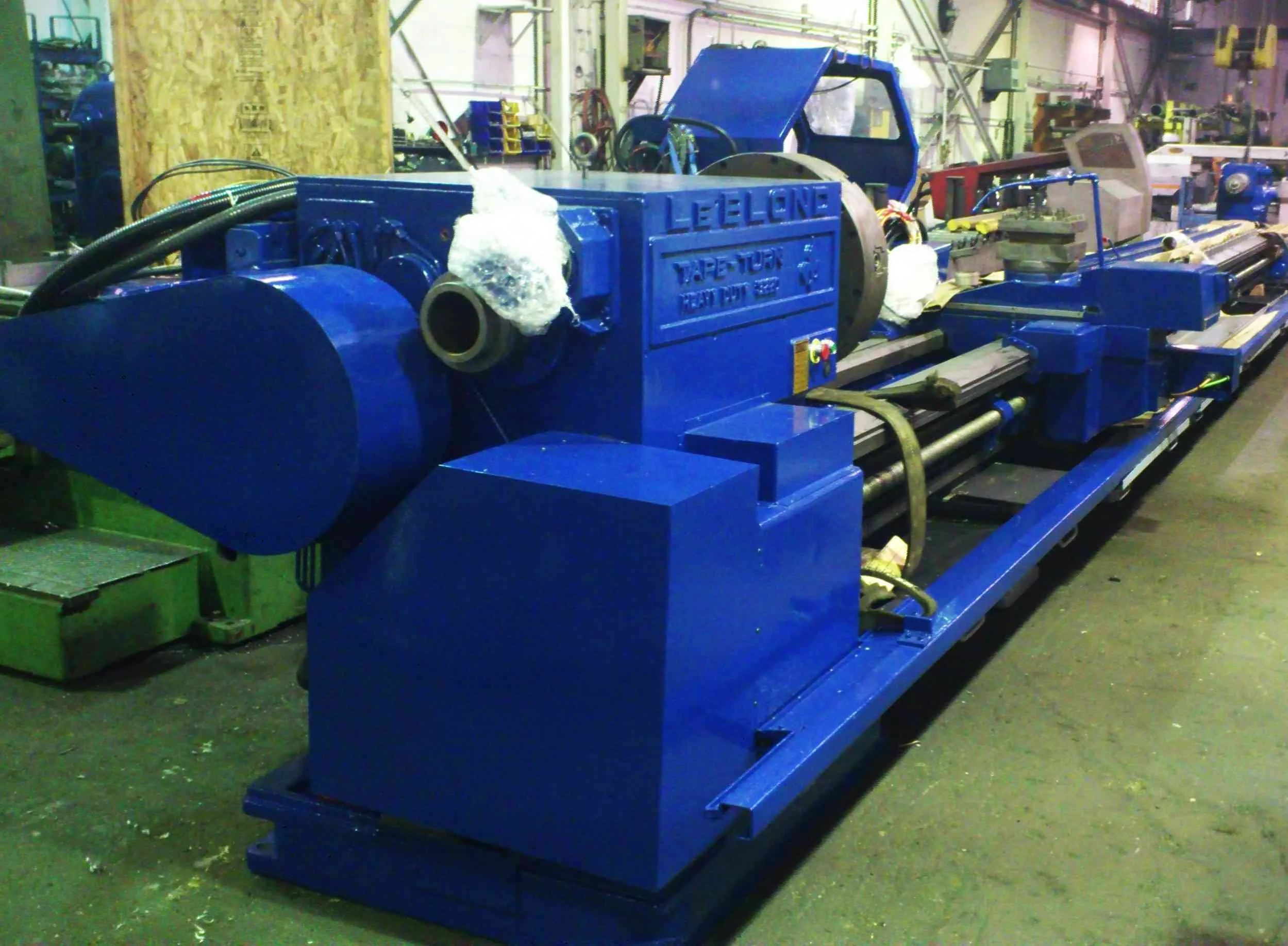

Frankor Deep Hole Drilling Machines

Frankor has specialized in manufacturing deep hole drilling machines for 25 years.

Deep hole drilling machines are use in a variety of different industries

Oil and Gas

Drill collars

Down hole tooling

casings

Refinishing spin casts for tubes

Aerospace

landing gear components

engine shafts and turbine parts

Nuclear

reactor components

generator shafts

Turbine rotor shafts

Hydraulics

Hydarulic Cylinders

Accumulators

What are deep hole drilling machines used for?

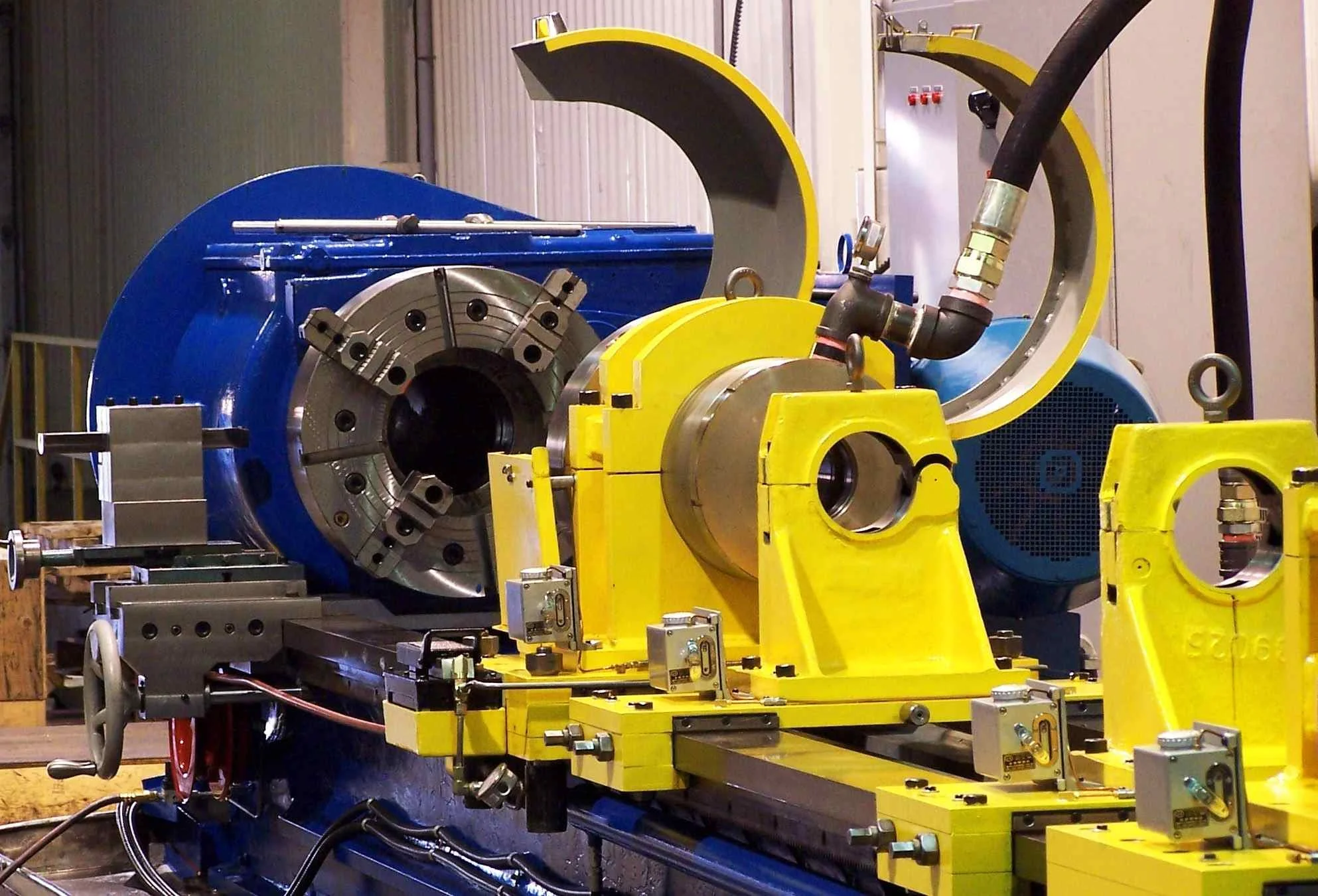

Deep hole drilling machines are specialized equipment used for very deep, precise and straight holes in large pieces of steel. they work by combining specialized drilling heads, high pressure coolant and precision guidance to to overcome the challenges of depth, chip evacuation and accuracy. They can generally bore larger holes holes at a faster rate than gun drilling.

What are the different functions of drilling machines

Deep Hole Drilling

This operation bores large, deep holes through large pieces of steel by using a hollow drilling tube and a pressure head. Coolant is pumped at high pressure around the outside of the drill tube, lubricating the cutting edges, breaking up the chips and then evacuating both the chips and coolant out through the hollow drill tube. Ideal for

Counter Boring

Counter boring is a secondary operation which can open up an existing hole hole and improve its finish and accuracy. it is also used to create steps within a bore and get rid of any tapers.

Pull Boring

This type of boring requires an existing hole wherein a boring tool is pulled through the piece and coolant flows through the tool and flushes the chips out the rear. This operation is used to improve the concentricity of a hole, make it straighter, improve the surface finish and give tighter tolerances.

Trepanning

Trepanning is preformed by using a hollow tube cutter with cutting inserts around the edge allowing a core to pass through. This type of deep hole drilling extracts a core instead of chipping valuable material and the core extracted may be repurposed. With this operation you get a large diameter hole with less energy, less time and less tool wear when compared to conventional drilling.

Honing

Honing is done with a mandrel fitted with abrasive honing stones which rotate and move in and out of a bore hole. this operation is used to finish the inside surface of a hole, achieving a high accuracy in size, straightness, roundness and creates a smooth cross-hatch pattern which is ideal for holding oil lubrication.